Chemical glycosylation technology

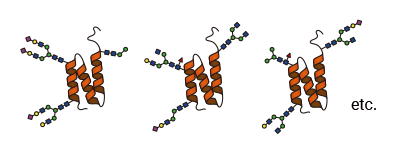

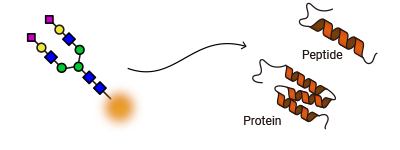

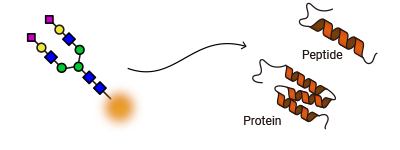

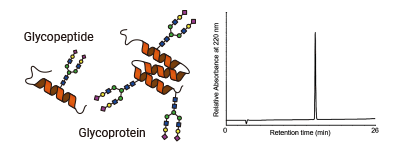

Based on collaborative research carried out with Professor Yasuhiro Kajihara of Osaka University, we have the unique ability to extract human N-glycans from abundant natural sources, such as chicken egg, on a large scale, and selectively attach them to a chosen peptide or protein at desired positions.

With these technologies, GlyTech, Inc. is able to offer a seamless route from glycan production to glycopeptide and glycoprotein synthesis for your research & development.

Our solution

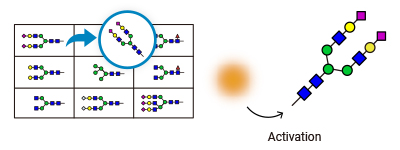

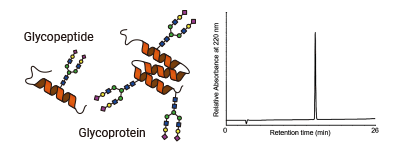

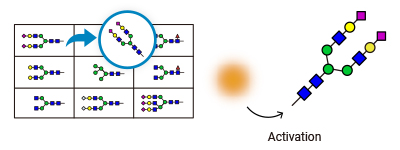

Unlike the cell culture systems traditionally used for the production of glycopeptide and glycoprotein therapeutics, the chemical synthesis methods that underpin GlyTech’s technology enable us to produce highly controllable, homogeneous glycan profiles and avoid the drawbacks of glycan heterogenicity. Our commercial manufacturing capabilities can help overcome the challenges associated with conventional glycosylation technologies: limited manufacturing scale, the extremely high cost of synthesizing complex glycan materials, and the difficulty of attaching glycans to target molecules.

- Traditional cell expression method

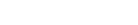

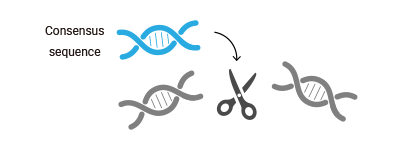

Insert glycosylation site(s) through DNA editing

Insert glycosylation site(s) through DNA editing

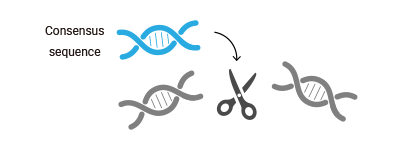

Discovery and production using cells

Discovery and production using cells

Heterogeneous glyco-forms, issue of biological impurities

Heterogeneous glyco-forms, issue of biological impurities

Complicated purification and characterization

Complicated purification and characterization

- GlyTech’s proprietary solution

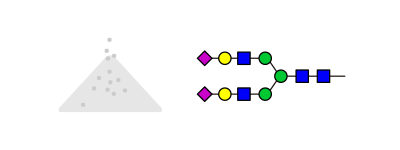

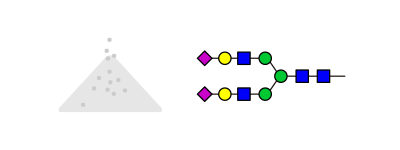

Building block glycan manufactured at a scale of

Building block glycan manufactured at a scale of

> 10 kg / year

Conversion of building block into different glycan structures and reducing end functionalization

Conversion of building block into different glycan structures and reducing end functionalization

Selective attachment of glycans to peptide, proteins, or other target materials

Selective attachment of glycans to peptide, proteins, or other target materials

Homogeneous compounds with controlled glyco-form

Homogeneous compounds with controlled glyco-form

| GlyTech’s proprietary solution | Traditional cell expression method |

|---|---|

Building block glycan manufactured at a scale of Building block glycan manufactured at a scale of> 10 kg / year |

Insert glycosylation site(s) through DNA editing Insert glycosylation site(s) through DNA editing |

Conversion of building block into different glycan structures and reducing end functionalization Conversion of building block into different glycan structures and reducing end functionalization |

Discovery and production using cells Discovery and production using cells |

Selective attachment of glycans to peptide, proteins, or other target materials Selective attachment of glycans to peptide, proteins, or other target materials |

Heterogeneous glyco-forms, issue of biological impurities Heterogeneous glyco-forms, issue of biological impurities |

Homogeneous compounds with controlled glyco-form Homogeneous compounds with controlled glyco-form |

Complicated purification and characterization Complicated purification and characterization |

Advantages of a chemical approach

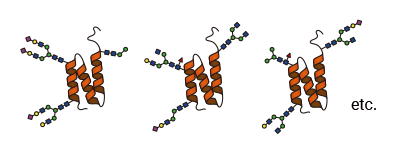

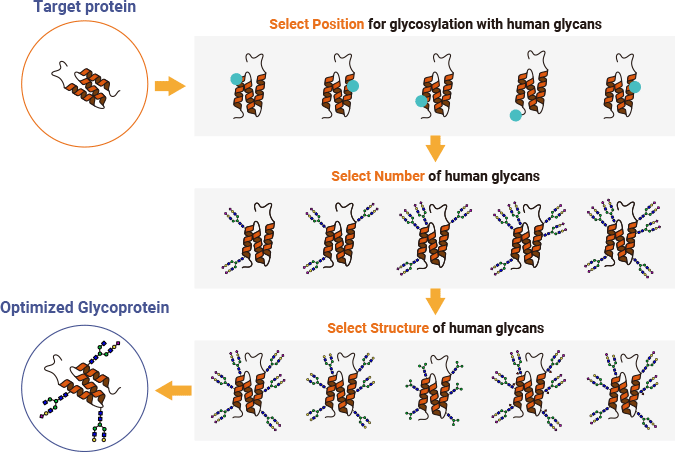

- Sequence-independent design: freely design glycosylation site, structure, and number, increasing the number of accessible glycan patterns

- Homogeneous product: simplify purification, characterization and QC during development

- Easily adaptable to target: from small molecule to DNA/RNA, peptides, proteins, and antibodies

- Compatible with various conjugation chemistries

Human-type glycan library

Our chemoenzymatic glycan production platform allows us to offer a library of over 50 highly pure and well-characterized glycan structures.

Our catalog features 4 types of N-linked glycan derivative (Asn-Fmoc, Asn, BrAc, and oxazoline) and 2 types of O-linked glycan derivative (Ser-Fmoc and Thr-Fmoc) for easy use in peptide synthesis and enzymatic trans-glycosylation. Other reducing terminal modifications and labels are available upon request to suit various other applications and custom requirements.

Glycosylated protein design / Glycoengineering

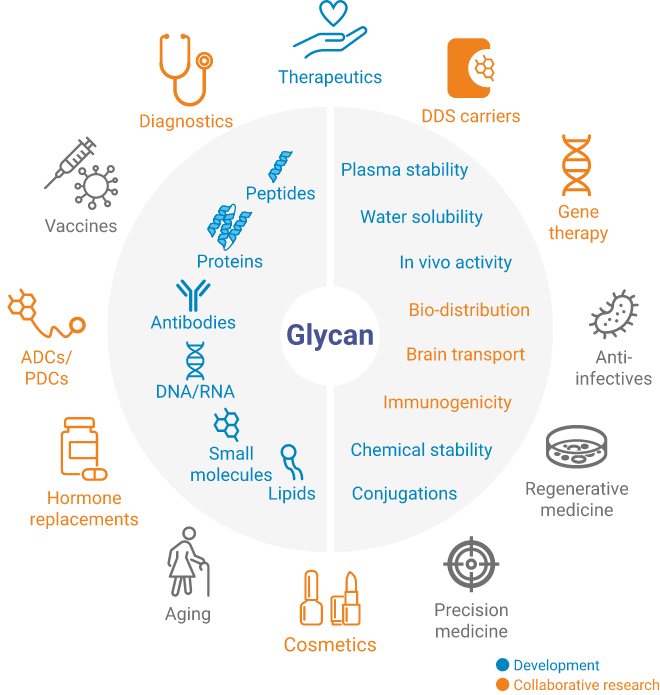

Enabling “biobetter” and novel glycoprotein drug discovery through rational design from glycosylation position to glycan structure to optimize drug properties and efficacy.

Partnerships and other applications

Our platform technology is compatible with various conjugation chemistries and easily adaptable to a wide range of compounds, from small molecule drugs to DNA, RNA, peptides, proteins, and antibodies. GlyTech has worked with many partners to provide glycan materials for new applications, including the development of ADC drugs using glycan linkers and the development of target-specific drug delivery systems.

We’re open to discussing new partnerships and excited to explore the potential of glycosylation together. Contact us today to get the conversation started.